Unleash Productivity in Your Storage Facility Workflow With a High-Quality Stretch Wrapping Device

Performance in storehouse procedures hinges on the effectiveness of the packaging process. The introduction of a top quality stretch wrapping device can be a game-changer, promising efficiency, reduced labor costs, and minimized human mistake. With the ability to take care of numerous tons sizes and wrap various pallets per hour, these devices provide a compelling proposition for any kind of service seeking to enhance its operations. What makes these makers such a critical possession in warehousing? Let's explore further.

Recognizing the Role of Stretch Covering Machines in Storehouse Operations

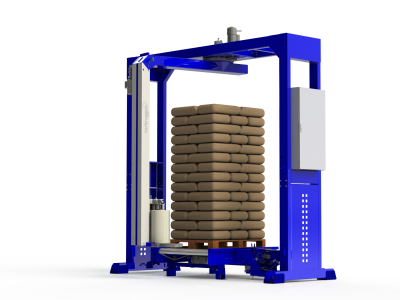

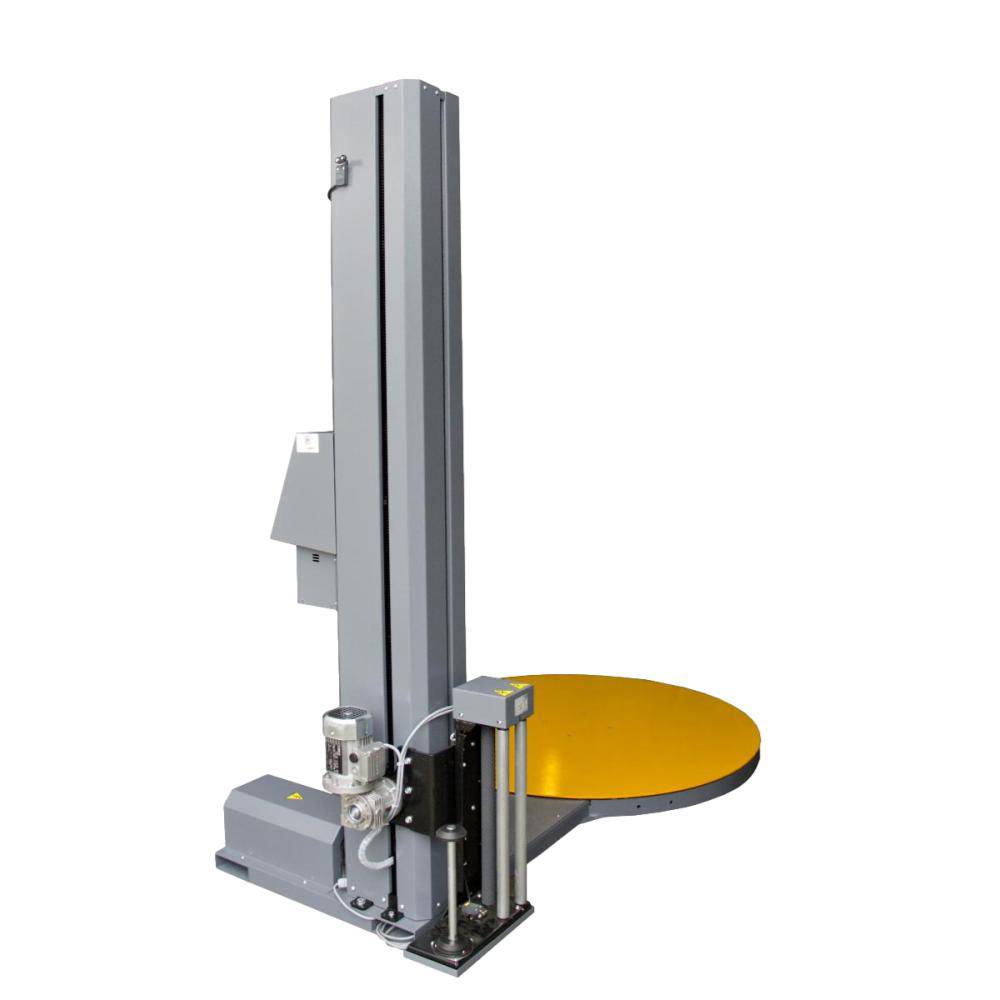

In the huge realm of stockroom operations, the significance of stretch wrapping machines can not be overemphasized. They serve an important role in ensuring that products are safely and firmly bundled for storage space or transportation. These devices apply a very elastic plastic film around items, securely covering them together in a manner that manual covering just can not match.

Efficiency is one more vital advantage. Stretch wrapping equipments can handle big quantities of products promptly, dramatically quickening the packaging process. This can lead to substantial time and price savings for services. In addition, the uniform wrapping supplied by these equipments can reduce the risk of meddling or burglary throughout transit.

Key Features of High-Quality Stretch Covering Machines

While there is a large range of stretch wrapping equipments readily available out there, premium models share specific key functions that set them apart. These makers are generally durable, designed to hold up against considerable use without jeopardizing on performance. They use a high degree of automation, permitting reliable and easy covering of products.

Top notch stretch wrapping devices additionally feature adjustable setups, offering adaptability to fit numerous packaging requirements. They can take care of different dimensions and types of lots, making sure a protected wrap each time. These machines are additionally renowned for their rate, efficient in covering many pallets per hour, thus dramatically improving productivity.

An additional key feature is their reliability and reduced maintenance requirement. Top notch equipments are built to last, reducing the frequency of malfunctions and the connected downtime. In addition, they run with accuracy, making certain consistent cover stress, therefore reducing waste and enhancing the discussion of covered items.

The Impact of Stretch Covering Equipments on Warehouse Performance

The effectiveness of a storehouse can be substantially enhanced with the use of top quality stretch wrapping equipments - stretch wrapping machine. These equipments enhance the look these up packaging procedure, minimizing the manual labor entailed and as a result, the opportunity for human mistake. This ensures an extra constant and reliable covering process, bring about enhanced safety and security of goods throughout transport

In addition, stretch wrapping makers can deal with a greater volume of products in a much shorter quantity of time compared to hands-on covering. This increased performance can lead to far better use of storehouse space as products can be packaged and moved faster. The makers likewise provide the flexibility to suit various sizes and basics shapes of goods, further enhancing functional performance.

Determining the Roi for a Stretch Wrapping Machine

Taking into consideration the substantial benefits of stretch wrapping machines, it's crucial to recognize the financial effects of purchasing such equipment. The return on financial investment (ROI) computation is a simple yet reliable tool to assess the productivity of this investment. The ROI Get More Info is computed by comparing the cost of the maker with the cost savings created over a certain period.

Organizations should also think about factors such as strategic positioning, functional efficiency, and scalability. In verdict, determining the ROI provides a clear financial viewpoint to direct the financial investment choice in stretch wrapping devices.

Real-world Study: Success Stories of Executing Stretch Covering Machines

Drawing from the economic implications discussed in the previous section, it is just as informing to take a look at functional applications and success tales of firms that have actually implemented stretch wrapping devices in their procedures. One such instance is an international electronic devices firm which reported a 30% decrease in harmed products throughout transit after presenting stretch covering devices in their packaging process.

Another success story entails a leading food and beverage firm. After executing a stretch wrapping device, they saw a substantial renovation in their product packaging speed, which in turn increased daily outputs and total efficiency.

Finally, a prominent furnishings supplier had the ability to lower their product packaging product expenses by an incredible 40% after switching over to stretch wrapping machines; they simultaneously decreased their carbon impact, making their procedures extra lasting. These real-world study demonstrate the outstanding returns and performance gains that extend covering devices can bring to storehouse operations.

Conclusion

To conclude, investing in a premium stretch wrapping equipment can considerably enhance warehouse operations. With its capacity to lower manual work, decrease errors, and boost area usage, it significantly boosts productivity and productivity. The ROI, combined with success tales from real-world executions, better emphasizes the crucial duty of stretch wrapping machines in achieving functional efficiency and organization success.

The intro of a top notch stretch covering device can be a game-changer, encouraging effectiveness, lowered labor costs, and lessened human mistake.In the huge realm of storage facility operations, the importance of stretch covering machines can not be overstated.The performance of a stockroom can be substantially boosted with the use of premium stretch covering equipments.Additionally, stretch wrapping equipments can take care of a greater quantity of goods in a shorter quantity of time contrasted to hands-on covering.In verdict, investing in a top notch stretch wrapping equipment can substantially improve warehouse procedures.